My blog has been pretty quiet lately and for good reason! I’ve recently relocated to Boulder, Colorado to join the Education Department at SparkFun Electronics. I’ll still be updating the blog with my personal projects, but to keep up to date on all the fun stuff I am making and teaching (including updates from our National Tour) please visit the SparkFun Education site.

My Hoops at Maker Faire

Here are a couple of detail pictures and videos of the hoop prototypes I brought to Maker Faire. I’ll have a longer post later in the week with all the cool stuff I saw and played with while wandering around the faire grounds. I wasn’t able to shoot great video at the faire because of the noise, so the two I included were shot in my hotel room (hooping indoors is quite a challenge!). I’m hoping to bring these pieces to a hoop jam and have some other hoop dancers try them out soon.

I mostly wore the sound making outfit around during the weekend, as my light up one was hard to see anywhere but inside the darkened Fiesta Hall. It was fun to wander through the crowds and do mini demos along the way. This is a slight variation on the beatbox hoop prototype I blogged about previously – instead of a hacked toy I used a LilyPad Arduino to make notes for each of the conductive patches. Many thanks to my fellow Seacoast Maker Alex Nunn for helping me with some last minute code on this one before I left for the faire. The nice thing about this particular jacket is that the board is completely modular; sewing snaps allow you to remove the LilyPad from the traces and speaker and pop in another one in the same configuration. I also used Sugru to add a finishing touch and a little extra protection to the connection between the snaps and the wires going to the LilyPad. I stopped by the Sugru booth and they loved the use of their product in wearables.

The first prototype is a little messy with some hot glue to make sure things didn’t fall apart with all the movement. The outfits held up well after two days of hooping, with only minor repairs needed.

I modded some gloves with conductive patches so that I could create effects while hooping on my hands as well. They snapped right into the sleeves of the jacket.

This is a completed version of my early experiment with LEDs. A small battery holder, conductive fabric, and LEDs make it a nice blink and bling example of my hoop-as-a-switch concept.

This little battery holder from Aniomagic worked well on the collar of this jacket. Unfortunately, it looks like they don’t make them anymore.

Hula Hoop Experiments

This summer I fell in love with hoop dancing and have been brainstorming fun ways to combine hooping and soft circuits.

Most of us have seen the fancy LED and fire hoops that make for great performances, but can it be taken a step further and have truly interactive hoops? Here are a few projects I’ve found that bring hooping to a whole new level. At the end of the post I’ve included documentation of some of my own early prototypes.

Lighting/Visual Effects

Uber Hoop

Christian Miller created the Uber Hoop – “The world’s most technologically advanced hula hoop! Features fully controllable RGB LEDs, a MEMS accelerometer and gyroscope, an embedded Arduino, and Bluetooth for wireless communication. The result is a hoop that responds to your motions and dazzles with beautiful light patterns!”

Fiber Optic Hoops

I’ve seen a lot of LED hoops, but fiber optic lighting is a fun twist. This one isn’t interactive, but still captivating to watch.

Controllers – Media and Music

Hula Rhythm

Images courtesy of Interaction Lab at Holon Institute of Technology

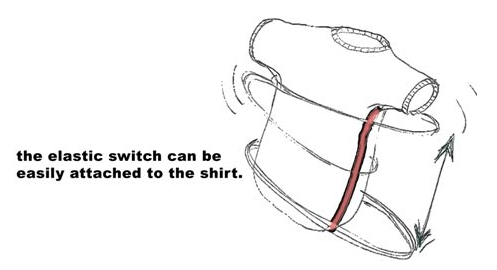

This project concept from the Interaction Lab at Holon Institute of Technology utilizes an elastic preassure sensor on the body to register the rotation/pressure of an ordinary hula hoop and translates it into a musical game.

Hip Disc

Image courtesy of Hooping.org

The Hip Disc uses conductive fabric on the edge of two hoop-like discs to trigger music. Not quite hooping, but it is an interesting new way of controlling music with your body.

Musical Hula Hoop – Fact or Fiction?

Hooping.org has a great article on the future of sound making/controlling hula hoops.

Anossens: The Game and The Reality

I really like this use of a hula hoop as part of an interactive game/live show created using Processing and webcams.

Data Logging

Smart Hula Hoop

Image courtesy of Electronic Products.com

The Smart Hula Hoop, created by a team of students from National Yunlin University of Science and Technology, uses an iNEMO board to “to transform the standard hula hoop into a complete healthcare sports monitor system. They did this by accessing and fusing together output data provided to the iNEMO by its on-board accelerometer (measures gravity and acceleration), e-Compass (measures absolute heading orientation), and gyroscope (measures angular velocity during exercise.)”

My Prototypes

I’m particularly interested in POV toys and if they can be successfully installed on a hoop in a seamless way. I’ve been talking with Instructables author Quasiben (who made a nice and simple Arduino POV) about creating a hoop that you can send text to through a smartphone and change the graphics on the fly. The video below is my first test to see if the hoop rotation was fast enough to display the text properly. Next step is to get the hardware into/on the hoop in a more permanent, clean way (right now it is just taped on the surface).

My other experiments have been playing with the idea of the hoop itself being a trigger, with most of the electronic components residing mostly on a garment. This solves the problem of bulky tech in such a small space. I’ve glued some conductive fabric tape on the inside of one of my hoops and have then been using patches of conductive fabric on various shirts as contact points. When hooping across these areas, the hoop acts as a switch.

Many hoop dancers use music with their performances, so what if you were able to create the music based on your movement? I’m experimenting with a beatbox drum machine toy to see if I can get some interesting flow happening. I’ll be bringing my prototypes to the Hoopium hoop jams to talk with more advanced hoopers about placement of electronics and feedback. Stay tuned!

http://www.flickr.com/apps/slideshow/show.swf?v=109615

Summer Vacation

After a whirlwind month of two maker faires – the Cambridge Mini Maker Faire and the Bay Area Maker Faire, I am ready to take a brief vacation from blogging. I’ll be working on a few projects throughout the summer and I hope to share them along the way or when I start blogging more often in the fall. See you then and enjoy your summer!

Here are a few pics from my trip to San Mateo for Maker Faire.

I had a great time doing a demo at the CRAFT booth on getting started with soft circuits. I had some examples of conductive threads, fabrics, and kits to show and pass around.

I met up with Dia, Sparkfun’s TechStyle Specialist, who had a cool sound-making dress with conductive flower petals and conductive threads as the triggers.

I got to stop by the Instructables HQ in San Francisco, so exciting! We made some liquid nitrogen ice cream and got a tour of the office.

Crochet Sensor Experiments

Here are a few tests of crochet stretch sensors (and some more knit sensors for comparison) as I try to determine the method that works best for me. I did a few experiments with crocheted vs knit sensors, conductive yarn vs conductive thread, and felted vs non-felted, and using elastic thread to see how each variation of the sensor would compare to the others.

I made a felted crochet stretch sensor following Felted Signal Processing’s Instructable – their method uses elastic thread to help add stretch and regular conductive thread along with wool yarn.

It was a little tricky keeping track of 3 strands while crocheting, and you can see from some of my pictures that I dropped a few stitches in places. I could only find the elastic thread in 11 yard spools, and these sensors (between 11″ and 15″) took about two spools each to complete. This type of sensor took more time and materials than the spool knit samples I made, but had a nice solid feel to it.

I was interested to see how felting the conductive yarn and knitted sensors would compare with the original sensor trials I had done, so I made a few more with variations. Here are the sensors before felting (from top to bottom):

A: Knitted sensor on 3 pin Wonder Knitter w/ elastic thread, wool yarn, and conductive yarn

B: Knitted sensor on 6 pin Wonder Knitter w/ elastic thread, wool yarn, and conductive yarn

C: Crochet sensor w/ elastic thread, wool yarn, and conductive yarn

D: Crochet sensor w/ elastic thread, wool yarn, and conductive thread

Here’s a side by side comparison of a felted sensor and the others ready for felting.

And all the finished sensors.

So how did they compare? Here is a chart of my results:

| Sensor | Resting Length | Resting Resistance | Stretched Length | Stretched Resistance |

|---|---|---|---|---|

| A | 15″ | 2.5 M ohm | 20″ | 12 K ohm |

| A (felted) | 12.5″ | >20 M ohm | 14.5″ | 3 M ohm |

| B | 17″ | 3.3 M ohm | 22.5″ | 4 K ohm |

| B (felted) | 13″ | >20 M ohm | 15″ | 2 M ohm |

| C | 11.5″ | 2.8 K ohm | 13″ | 1.2 K ohm |

| C (felted) | 10″ | 1.7 M ohm | 13″ | 1.3 M ohm |

| D | 11″ | 20 ohm | 13″ | 15 ohm |

| D (felted) | 9.5″ | 38.5 ohm | 11″ | 35 ohm |

The crochet sensors, while nice and sturdy, weren’t really all that stretchy. I also noticed that they didn’t bounce back, and over time would stretch longer and longer. Maybe a different type of elastic would help with this issue.

The conductive thread sensors also need to be very long in order to get a large range of values, so I think the knit sensors with conductive yarn will be the way to go for hooking up to a drawdio.

Making Knit Stretch Sensors

This week my order of Nm 10/3 Conductive Yarn from Plug and Wear arrived. I immediately started making some samples of the knit sensors I blogged about a few weeks ago.

Following Hannah Perner-Wilson’s tutorial/method, I made two sensors using a Wonder Knitter from the craft store. It came with two attachments, a 3 pin and a 6 pin to make a thinner and thicker knit tube.

After making two knitted sensors with a combo of acrylic yarn and conductive yarn, I made my own knitting spool out of an old thread spool and some nails. I used some sock weight yarn in a similar thickness to the conductive yarn and made a nice thin sensor.

Here are the three sensors I made side by side. They are about 15 inches long with tails to connect the conductive yarn to alligator clips for testing.

Resistance readings from my multimeter:

- Sensor C: 6 pin knit on Wonder Knitter – Resting 4.45 M ohm, Stretched: 10 K ohm

- Sensor B: 3 pin knit on Wonder Knitter – Resting: 3.9 M ohm, Stretched: 10 K ohm

- Sensor A: 3 pin custom spool knitter and sock weight yarn – Resting: 1.0 M ohm, Stretched: 10 K ohm

After doing some more tests, I’m going to start prototyping a knit version of my Musical Drawdio Puppet using the sensors as the tentacles so that you can ‘play’ it by pulling on them.

I’ve also been teaching myself to crochet and will be trying out more techniques soon. I made a crochet button using the example on How To Get What You Want.

Hooking the sensors up to an LED to control brightness:

Project: Anglerfish Theremin Plush

Awhile back I purchased a couple of Gakken Mini Theremins to play with. They are the perfect size to embed into stuffed toys (the magazine that came with the kit even has an example with a plush dog toy). Around the time that I was getting ready to head to the World Maker Faire, I had the idea to use one of these mini theremins and put it into an anglerfish puppet – the bendy antenna would be the perfect size for the fish’s lure. I originally started making a fish out of fleece but found it was hard to hold it’s shape. I put the project on hold while I got everything ready for the faire and it got ignored for awhile.

In the past few weeks I have been teaching myself to crochet and making some amigurumi critters. I was looking online for some new patterns to try and remembered my anglerfish project – why not try and crochet one? Since I couldn’t find a pattern to follow I decided to make up my own version. While a little cartoony, I’m happy with the result.

Once I had a basic fish, I prepped the mini theremin to go inside. I ditched the red case the circuit board came in and replaced the AA batteries with AAA in a holder with an on/off switch.

I also replaced the antenna with a sturdier one from an RC car. The final touch was adding an LED for the anglerfish’s lure and as a power indicator.

Once everything was hooked up I put the board in a small plastic box to protect it, and threaded the LED and antenna into the plush’s antenna. I found that if the wires from the LED were too close to the antenna wire it would cause interference, so I ended up attaching them along the outside and covering them with a whip stitch.

Everything went into a pouch inside the fish to keep it from getting tangled in the polyfil I used to stuff it. Velcro along the edge makes for easy access to the battery pack to turn it on/off.

Packed up and ready to play! So far, the antenna isn’t very sensitive so you have to be right up close to the fish to get any change in the sound. I had the same problem when the theremin was set up as a kit before hacking it, and am looking for a way to get a better range. There are some potentiometers on the board for adjusting and I saw something about using tin foil to ground it through the battery pack, so I’ll try a bit more and see if I can some better sounds out of it. If I get some good results, my next step is to add an audio jack to hook it up to an amp, and maybe turn the eyes into knobs for on-the-fly adjustments.

World Maker Faire Recap

It’s been one week since I traveled out to Queens to experience the first World Maker Faire at the New York Hall of Science. I had an amazing time seeing some familiar faces of my fellow makers and meeting lots of new and interesting participants and faire-goers.

The event had a bit of a different feel than the Bay Area Faire back in May. Many of the makers were outside in tents, lending it more of a craft faire or street faire feel than the expo setting of everyone gathered together in a big warehouse. I was located near the CRAFT area and close to the Bust Craftacular where it was a little more low key than the main traffic areas.

Many of the makers were located inside the New York Hall of Science scattered between the museum’s permanent exhibits. It was an interesting (though sometimes confusing) combination of the stationary exhibits and the maker booths.

CRAFT Demo

In addition to displaying my projects at a booth, I was also invited to do a demo at the CRAFT booth on my ‘Talking’ Sock Puppets. There was a great turnout and I had a lot of fun talking to folks after the demo about how they could make their own noise making puppets at home. The puppets even earned an Editor’s Choice blue ribbon – they were a big hit with kids and adults alike.

Other Soft Circuit Makers

I was lucky enough to have the folks of Fabrickit as my neighbors during the faire. They launched their new product line and I was able to chat with them about it and purchase a kit to bring home and try out. I will be posting soon about my experience with their modules.

Inside the Hall of Science I stopped by Sarah and Lara Grant’s Felted Signal Processing table – they are using conductive and metallic fibers combined with wool to felt their own sensors and controllers for sounds. The pieces have a wonderful texture and sculptural quality to them.

Many of the other soft circuit and wearables makers who presented at the faire were also in the eTextile Fashion Show organized by Lynne Bruning. Unfortunately it was scheduled at the same time as my sock puppet demo, but my friend Rebecca was able to capture some video of it for me to compile and share.

The Rest of the Faire

While I wasn’t able to experience the full faire, the friends who traveled with me were nice enough to watch my booth a few times so I could wander around and see some things for myself. I watched a Life Size Mousetrap performance and caught the last Arc Attack show of the weekend, two things I regretted not being able to see in person while wandering around the Bay Area Faire. Many thanks to Rebecca, Erin, and Randy for their help with photography and video of the faire!

Getting Ready For World Maker Faire New York

I’m happy to announce that Soft Circuit Saturdays will be at the first World Maker Faire in New York next month! This will be my 3rd time attending a Maker Faire event, and the first time I will be participating in one of the ‘big’ faires with a booth and projects to share. It’s going to be an amazingexperience to be in the midst of so many people – I’m very excited!

I will be bringing a few things I shared atCambridge Mini Maker Faire, along with some new pieces. I’ve decided to make sure that most of the projects that I bring along will have tutorials and DIY instructions available either on this site, Instructables, or Make:Projects. That means I’ll be spending the next few weekends putting together how-tos, getting everything prepped for the faire, and finalizing my travel plans. Instead of my weekly posts of projects and builds, I will be posting links to interesting projects I find on my Facebook page, and possibly publishing a round-up or two along the way.

I have a few friends who will be traveling with me to help document the faire and the other soft circuit projects and makers that will be there, so stay tuned for photos and videos in the weeks after the event.

Here are the projects I’m bringing (so far):

- Drawdio Puppet

- LED Jellies

- Talking Sock Puppets

- LilyPad Pillow

Check out all my tutorials over on Make: Projects to learn how to make your own versions of these pieces.

Exploring Make: Projects

A few weeks ago, Makezine & Craftzine introduced a new DIY platform called Make: Projects. Soon after the site launched, I jumped right in and started posting some of my project tutorials and playing around with the system.

Make: Projects is a living library for makers, a how-to community hosted by MAKE magazine! Here you can build something from our growing cookbook of projects, tweak existing projects to improve them, share your own step-by-step instructions, discover new ideas and techniques, and learn how to make just about anything. And it’s a wiki, so everything is hackable. Connect with the collective smarts of the maker community!

Interface and Features

When you create a new guide, it is broken into three sections that you edit separately:

- General Guide Data – input a title, choose a category for your guide, intro text, and a one line summary (that displays when browsing projects).

- Meta Data – display approximate time & difficulty of the project, prerequisites, and list the tools/materials needed.

- Steps - the ‘meat’ of the guide, where step-by-step instructions and images go.

Tools Database

A really cool feature of the platform is the tools and material database in the Meta Data section of the guide editor. As you start typing a tool into the box, the database searches for it and you can choose from a drop down list. If the tool you input is not in the list, it gets added to the database, building a larger collection of relevant materials.

Template

The steps pages are created in a specific template, broken down into bullet points with icons that can be added for notes or reminders. This forces you to keep the steps short and to the point. As I was inputting tutorials I had previously published on Instructables, this constraint helped me clarify and condense instructions and make them easier to follow.

Images

One of my favorite aspects of the platform is the image tray. A pop up at the bottom of the screen, you can upload a bunch of images and drag and drop them into different sections of your guide. Once you use the image it is removed from the tray, but can be dragged back into it for rearranging.

Make: Projects vs Instructables

So how does the Make: Projects platform compare with the well known Instructables? It is hard to compare them side-by-side as they are essentially about different things. Make: Projects appears to be more of a library of tutorials introduced in Makezine and Craftzine, with the ability for users to contribute their own projects. It has more of a database/magazine feel and is for browsing, editing, and using as a reference. The strength of Instructables lies in its community and social emphasis on making. There are forums, comments, and ratings systems to help bring the most useful or engaging content to the forefront. One major difference to note is that on Make: Projects everything must be licensed underCreative Commons BY-NC-SA, while Instructables has the option of all Creative Commons licenses. I don’t favor one over the other and publish my tutorials on both to reach different audiences. It will be interesting to see how the two sites interact with each other.

Make: Projects

Pros:

- Standardized formatting keeps an easy to read and cohesive look/feel to the content.

- Wiki-based editing allows for guides to be continually improved upon.

- Curated platform helps eliminate duplicates and keeps a higher standard of projects.

Cons:

- Only 3 images allowed per step.

- No option to embed video (yet).

- Some users may find Wiki formatting/syntax confusing

Instructables

Pros:

- Thriving community adds a social aspect to the tutorials, commenting, contests and badges encourage interaction between users.

- Tagging, keywords, ratings, favorites and subscription options to organize your own priorities andenable dynamic browsing through related tutorials.

- Ability to add notes to images.

Cons:

- Lots of ads can make interface crowded unless you purchase an upgraded account.

- No rules in place for formatting or image resolution – content/quality can be hit or miss.

Click the image below to check out my author page on Make: Projects and view some of my tutorials.

[all images via Make: Projects]